Gloster Engineering Ltd

Ph 07 846-7714 | Fax 07 846-7715

E-mail: [email protected]

Address: : 9-11 Newton Place,

Hamilton

Capabilities

We machine in a full range of materials:

- Brass

- Stainless Steel

- Plastics

- Steel

- Aluminium

- Casting

We can offer customers expertise in areas of design and prototype, and also design improvements as required. CAD drawings are available by expert draught persons.

A Variety of finishes are available in:

- Chrome and Zinc plating

- Powder coating

- Anodizing

- Nickel and Gold Passivating

Gloster Engineering has both the capacity and ability to supply our Customers with Finished Product solutions from Design to Production.

This is achieved through our main capabilities which include:

- CAD Facilities

- CNC Cutting facilities (Up to 250mm Diameter Capacity)

- CNC Mill Turn Centres (Unmanned Night Running Capacity, Up To 65mm Diameter Bar Feed Capability, Up to 300mm Diameter Billet capability)

- CNC Twin Pallet Machining Centre (Table Size 560mm x 400mm)

- CNC 4 Axis Machining Centre (Table Size 1100 x 550)

- CNC Teach Lathe (Spindle capacity to 102mm in Diameter, Billet capacity 300mm Diameter)

- Automatic and Manual Lathes (Automatic Bar Feed capability to 25.4mm Diameter, Manual Lathes to 102mm Diameter Bore and 300mm Billet)

- Drilling and Tapping machines

- Manual Milling Machines (Table Size 1500 x 300)

- Mig / Tig Welding, Soldering and Braising (Mild Steel and Stainless Steel Separated to avoid Cross Contamination)

- Clean Assembly Area, (Located away from the Workshop)

gloster case studies

Shear & Swivel Couplings for Fonterra

GPS docking station for Smartrak

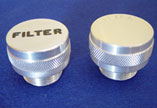

Custom

jobs